-

- CNC Turing Yinchuang is a professional manufacturer of precision mold parts. Our CNC turning service can be used to process designs from simple pieces to complex precision mold parts according to your blueprint specifications.

-

- CNC Surface Grinding Yinchuang provides high-quality surface grinding services thanks to years of processing experience in the industry. Our factory is equipped with CNC grinders and manual grinders with wheels that rotate and grind workpieces to reach the required flatness.

-

- Wire EDM CNC wire EDM (electrical discharge machining) machines harness a controlled electric current to process various complex shapes using electrochemical corrosion.

-

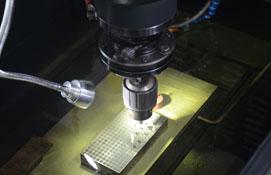

- CNC Milling Yinchuang has the tools, technology, and training to apply CNC milling in any project from start to finish. Whether you need precision gauges, fixtures, stamping dies, molds, prototypes, or production runs, Yinchuang has the CNC milling services to fulfill all of your requirements.

-

- ID/OD Grinding Here at Yinchuang, we utilize high speed grinding wheels to finish the surface of various products. We operate with high accuracy and uniformity to meet your specialized needs.

-

- Small Hole EDM Drilling Most EDM drilling machines are CNC-controlled, however, some are actually mounted on the table of a CNC mill. By retrofitting an EDM driller onto a CNC mill, Yinchuang offers micro hole and small hole EDM drilling services on parts over 2,200 lbs and in excess of 40" long.

- Home

- Metal Processing Service

- Sinker EDM

Sinker EDM is an ideal solution for the processing of low risk molds and parts. Yinchuang has rich experience in EDM machining, so we offer services with our current sinker EDM and staff, like processing mold parts or small parts. We offer reliable and precise low risk machining services.

The advantage of the sinker EDM is that it will process the material into various complex shapes without influencing the stress.

SINKER EDM CAPABILITIES+/- 0.0002” TOLERANCE: Typical tolerance, but can vary due to type of material.

C-AXIS ROTATION: Rotation around the Z-axis allows for threaded holes in hardened materials.

12” X 10” x 10” WORK ENVELOPE: Fully-submersed in an oil bath to increase erosion rate.

32 RMS OR HIGHER: Slower feed rates increase surface finish, but increase electrode wear.

ALL CONDUCTIVE MATERIAL: Burns soft or hard metals, including carbide.

REPAIR DAMAGED HOLES: Clean out damaged walls without affecting geometric position.

A chief benefit of the sinker EDM is the ability to produce complex shapes without influencing stresses into the material. Since the electrode is sunk, or lowered, into the material, it must be wider towards the top of the plunge than at the bottom.

Unlike wire EDM, sinker EDM does not cut all the way through the material (unless desired). As a result, sinker EDM has a wider variety of applications, such as blind cavities/keyways, thin walls, or cross sections. This versatility makes sinker EDM an efficient technology for stamping dies and injection molds.

Since the reverse image must be machined out of graphite, it is encouraged that the customer provides a 3D model. The more complex the required electrode is, the costlier sinker EDM can become.

If you are interested in this product, feel free to contact us anytime!