- Home

- Capabilities

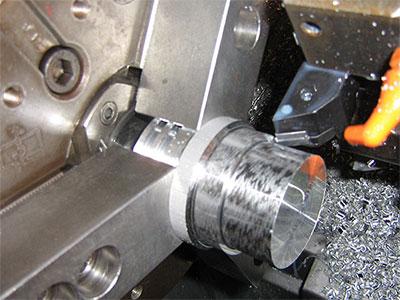

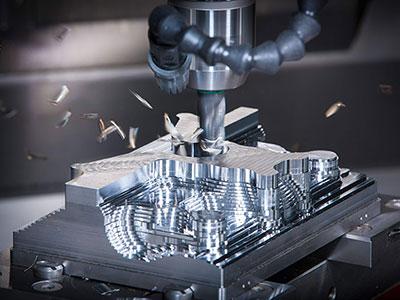

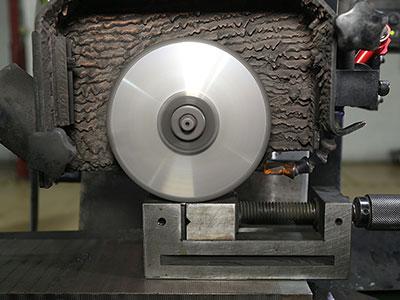

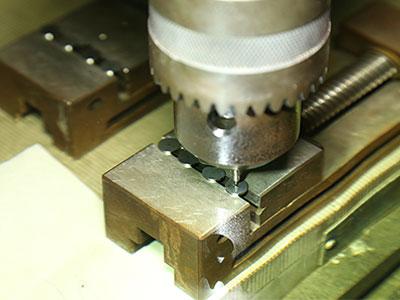

CNC machining is an essential process for building parts and assembles such as bearings, housings, pins, bushings, blocks, custom nuts, bolts, screws, and more. Yinchuang has the equipment and skills needed to deliver these parts and assemblies to our customers. From our fully automated CNC machining equipment to our tool room mills and lathes, we guarantee the best quality in all aspects of our machining processes.

- Turning

- Milling

- Grinding

- Drilling

- Sawing

- Tapping

- Countersinking

- AutoCAD

- Solidworks

- ProEngineer (Pro-E)

- DXF, IGES, STEP for direct importation into our CAD systems.

- PDF, TIF, JPEG, BMP, PNG, and EPS (for graphics)

From prototypes to 10,000 pieces annually

- Discrete orders

- Blanket orders

- Quarterly Buys

- Annual Contracts

- Value Add Engineering

- Lean Initiatives

- XYZ Travel (Spindle Movement Range): 40″ x 20″ x 25″

- Rapids on X, Y, Z: 1,400 in/min

- Inline Direct-Drive Spindle Speed: 12,000 rpm

- Maximum Cutting Rate: 833 in/min

- Table Width: 18″

- Table Length: 48″

- Maximum Weight (On Table): 1750 lbs

- Tool Capacity: 24 + 1

- Tool Change Time (Tool-to-Tool): 1.6 seconds

- Tool Change Time (Chip-to-Chip): 2.2 seconds

- Maximum Tool Diameter (w/ full pockets): 3″

- Maximum Tool Diameter (w/ no adj. tools): 6″

- Maximum Tool Weight (w/ full pockets): 12 lbs

- Maximum Turning Diameter: 14″

- Maximum Turning Length: 20″

- X, Y, Z Travel: 10.2″ x 3.9″ x 23.2″

- Maximum Spindle Speed: Headstock 1: 5,000 min-1

- Headstock 2: 6,000 min-1

- Maximum Number of Tool Stations: 20

- Maximum Rotary Tool Spindle Speed: 6,000 min-1

In compliance with and certified to ISO 9001:2015.

Direct etching onto your machined part in the CNC turning center.

High speed machines run automatically, based on input from the user or automation

The quality control department utilizes special equipment to thoroughly review products for quality before they are shipped to you, including but not limited to, InspectVision, Romer Arm, Height Gauges, Calipers, Micrometers, and Precision Linear Scales.

Industry standard tolerances apply or estimated and built to customer specifications.

Multiple Metals and Alloys

For complex parts with tight tolerances, our Swiss machines work with a variety of metals and alloys:

- Alloy Steels (4130, 4140, 4340, 8620, 9310)

- Aluminum (2011, 2017-T4, 2024, 6061 -T6, 7075-T651)

- Beryllium Copper

- Brass

- Bronze Alloys

- Carbon Steel (1018, 1117, 1141, 1144 Stressproof, 12L14, 1215)

- Copper

- Stainless Steel (13-8, 15-5, 17-4, 303, 303SE, 304, 316, 321, 410, 416, 420, 440C, Nitronic® 60, Monel)

Request a Quote? Feel free to contact us at any time!

click here