-

- CNC Turing Yinchuang is a professional manufacturer of precision mold parts. Our CNC turning service can be used to process designs from simple pieces to complex precision mold parts according to your blueprint specifications.

-

- CNC Surface Grinding Yinchuang provides high-quality surface grinding services thanks to years of processing experience in the industry. Our factory is equipped with CNC grinders and manual grinders with wheels that rotate and grind workpieces to reach the required flatness.

-

- Wire EDM CNC wire EDM (electrical discharge machining) machines harness a controlled electric current to process various complex shapes using electrochemical corrosion.

-

- ID/OD Grinding Here at Yinchuang, we utilize high speed grinding wheels to finish the surface of various products. We operate with high accuracy and uniformity to meet your specialized needs.

-

- Small Hole EDM Drilling Most EDM drilling machines are CNC-controlled, however, some are actually mounted on the table of a CNC mill. By retrofitting an EDM driller onto a CNC mill, Yinchuang offers micro hole and small hole EDM drilling services on parts over 2,200 lbs and in excess of 40" long.

-

- Sinker EDM Sinker EDM is an ideal solution for the processing of low risk molds and parts. Yinchuang has rich experience in EDM machining, so we offer services with our current sinker EDM and staff, like processing mold parts or small parts.

- Home

- Metal Processing Service

- CNC Milling

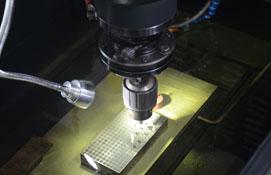

Yinchuang has the tools, technology, and training to apply CNC milling in any project from start to finish. Whether you need precision gauges, fixtures, stamping dies, molds, prototypes, or production runs, Yinchuang has the CNC milling services to fulfill all of your requirements. With an impressive amount of exotic material experience, Yinchuang often takes on R&D projects other companies cannot handle. We have produced CNC machined parts that are used under the ocean, outside of the atmosphere and everywhere in between.

CNC MILLING CAPABILITIES+/- 0.0005” Tolerance: Typical tolerance, but can vary due to size and type of material.

Stamping Dies and Molds: Project management experience for die or mold sets, from start to completion.

42” X 24” X 24” Work Envelope: Multiple CNC machines running over multiple shifts.

3-, 4-, & 5-AXIS Machining: True 5-axis milling, featuring a 360-degree C-axis rotary table with 150-degree trunnion.

All Metals/Alloys/Plastics: Thread or mill any metal, including stainless steel, aluminum, and more.

8 RMS or Higher: With the right speed and feed, Yinchuang can CNC mill an 8 RMS surface finish.

With various tooling setups and ingenuity, CNC milling can be applied in the production of almost any shape. The wide range of potential milling applications also makes CNC machining the most flexible service Yinchuang has to offer. Tolerance, surface finish, part size, tooling, and material properties can all affect pricing.

Whether a part is suited for 3-, 4-, or 5-axis milling depends greatly upon the dimensions and features of the part itself. In general, fewer setups are needed for milling machines with more axes. Achieving the greatest geometrical precision possible in a single setup ensures greater feature-to-feature accuracy.

Multiple-axis machinery requires complex, skillful, and meticulous programming. Providing a 3D CAD file can generally reduce time spent quoting or programming CNC milling code.

If you are interested in this product, feel free to contact us anytime!